Welcome to Mapple Leaf, a trailblazer in biodegradable solutions, and Garvit Green Industries Private Limited, the powerhouse behind its innovative manufacturing processes. In an era where sustainability is paramount, the need for eco-friendly alternatives to conventional products has never been greater. Together, they are redefining the landscape of sustainable packaging through the production of sugarcane bagasse products. Let’s delve into the impressive journey of how our products come to life, accentuated by immense hard work and dedication.

Know Our Main Ingredient

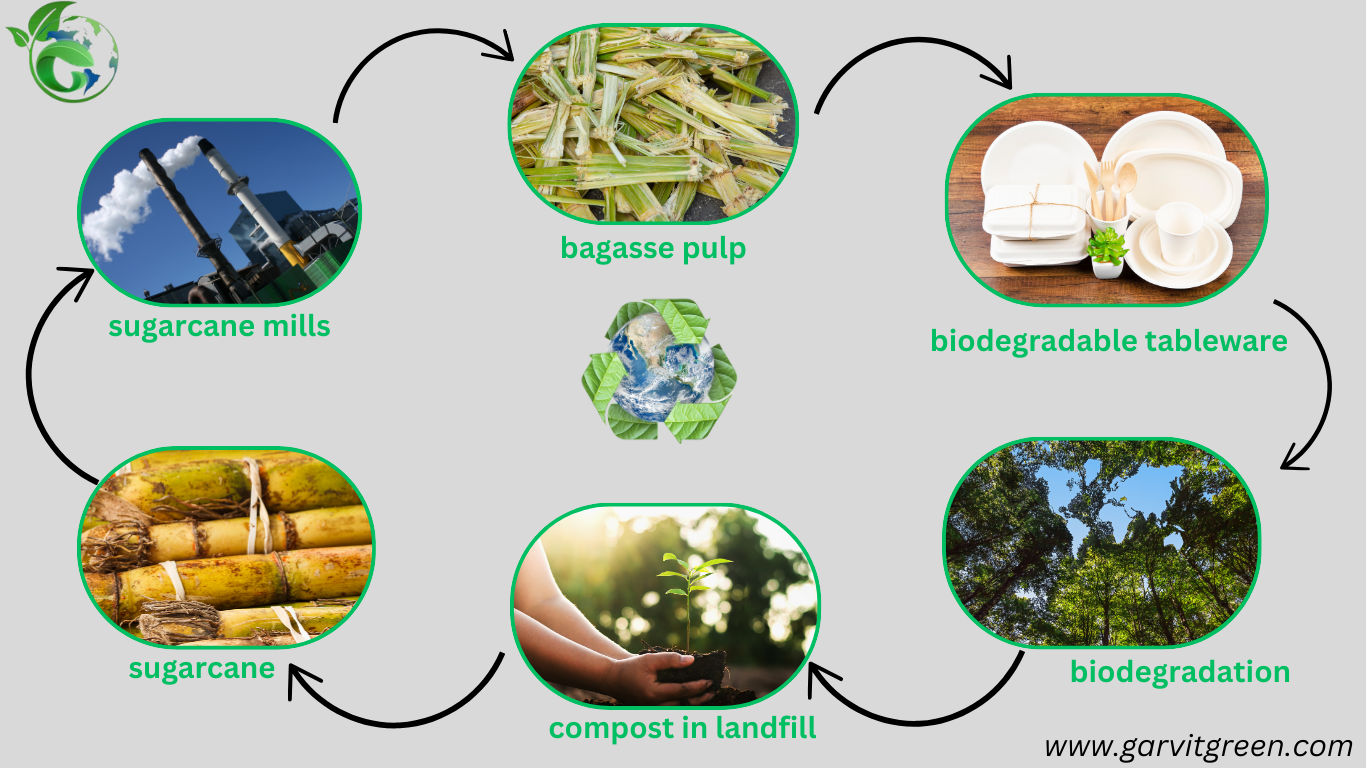

Sugarcane bagasse, the fibrous by product of sugar extraction, is often discarded or burned, contributing to environmental degradation. However, Mapple Leaf has tried to turn this challenge into an opportunity. By transforming bagasse into biodegradable packaging products, we not only reduce waste but also create a sustainable alternative to plastic. This innovative approach embodies the principle of circular economy, where waste is reformulated into valuable resources.

The manufacturing of biodegradable tableware: A Symphony of Hard Work

1. Sourcing Raw Materials

The journey begins with the careful sourcing of high-quality sugarcane bagasse. The manufacturers collaborate closely with local sugar mills to ensure a consistent supply of fresh bagasse. This commitment to local sourcing not only supports the regional economy but also minimizes the carbon footprint associated with transportation.

2. Preparation and Processing

Once the bagasse is procured, it undergoes rigorous preparation. The fibrous material is cleaned, shredded, and dried to achieve optimal moisture content. This step is crucial as it ensures that the bagasse is ready for the subsequent stages of processing. The manufacturing team is equipped with state-of-the-art machinery and it works diligently to ensure that every single product meets the highest standards of quality.

3. Pulping and Moulding

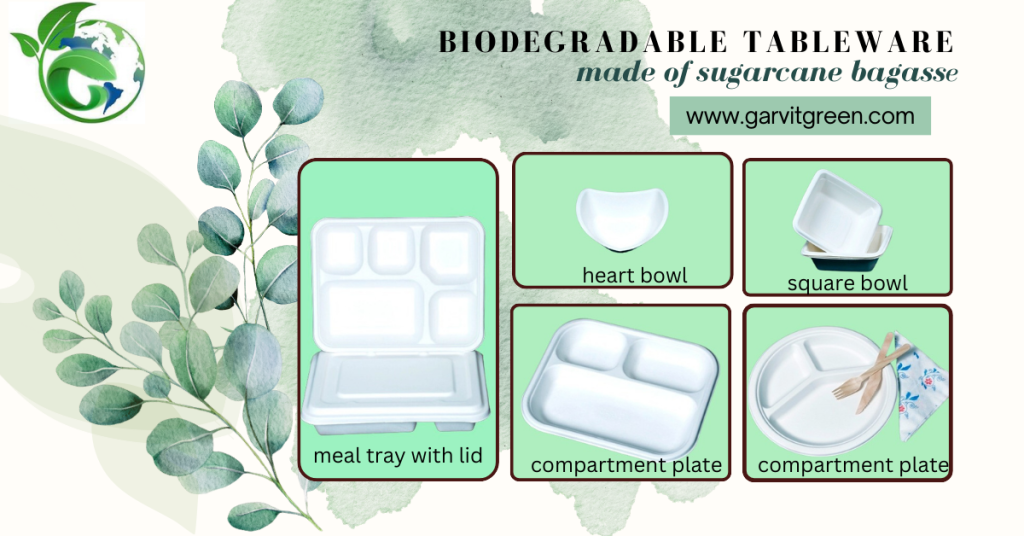

The next phase involves pulping the prepared bagasse. Using eco-friendly chemicals, the fibrous material is transformed into a pulp that can be moulded into various shapes. This process is labour-intensive , requiring skilled technicians who meticulously monitor the consistency of the pulp. Once the ideal texture is achieved, it’s time for moulding , where the pulp is shaped into products such as plates, bowls, clamshell boxes, trays etc.

4. Drying and Finishing

After moulding, the products are carefully dried in controlled environments to ensure durability and strength. This step is prominent in order to prevent deformation and ensure that the final products can withstand various conditions. Following drying, each product undergoes final touches, including trimming and quality checks, to guarantee that it meets the uncompromising standards set by Mapple Leaf.

5. Quality Assurance

At Garvit Green Private Limited, quality assurance is of utmost importance. Every product is subjected to rigorous testing to ensure it meets both safety and environmental standards. This commitment to excellence not only enhances the reputation of Mapple Leaf products but also builds trust with our consumers who are increasingly mindful of their environmental impact.

Garvit Green Industries is not just focused on manufacturing; we are dedicated to fostering a culture of sustainability. The entire production process is designed with eco-friendliness in mind. From utilizing renewable energy sources to minimizing water usage and waste generation, every step reflects a deep commitment to protecting our planet.

The biodegradable sugarcane bagasse products manufactured by Garvit Greens Industries have garnered attention for their functionality and environmental benefits. With the capability to decompose naturally within a short period, these products serve as a practical alternative to plastic, addressing the global plastic crisis. Moreover, they offer businesses and consumers a sustainable choice without compromising on quality or convenience.

A Bright Future Ahead

Mapple Leaf by Garvit Green Industries stands as a testament to what can be achieved when hard work, innovation, and sustainability intersect. As we continue to confront the challenges posed by environmental degradation, our initiative will definitely pave the way for a greener future. Together, we can foster a world where eco-friendly practices become the norm, not the exception. Maple Leaf, with the dedicated efforts of Garvit Green, is leading the charge—and the journey has only just begun. By choosing biodegradable sugarcane bagasse products, consumers are not just making a purchase; they are making a statement. They are joining a movement towards sustainability, supporting local economies, and championing the planet.

Hi garvitgreen.com administrator, Your posts are always well researched.

Thank you sir